11, 2019

by Oree Laser

Carbon steel is the most common material in metal processing, and laser-cut carbon steel plays an important role in the metal processing industry. As far as the cutting process, the difficulty of adjusting thick carbon steel plate is several times higher than that of a thin carbon steel sheet. It is necessary to consider not only the high standard processing requirements of the customer but also the cost of the later stage.

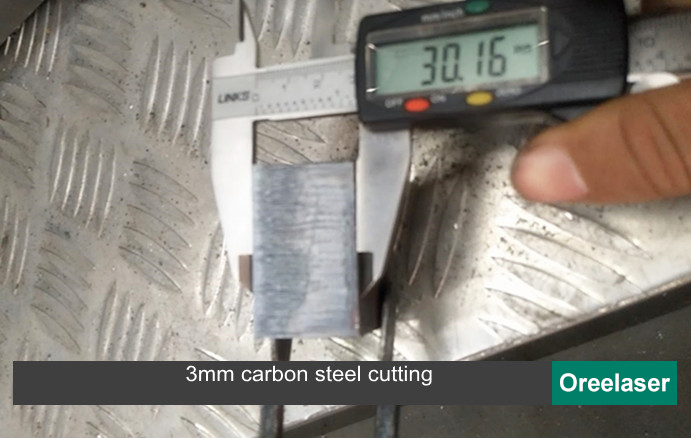

30mm carbon steel limit refresh

As the thickness of the carbon steel plate increases, the cutting data such as laser power and cutting process parameters should be adjusted accordingly. Oreelaser P series 6000W full-protection fiber laser cutting machine will refresh the carbon steel cutting limit to 30mm again!

Oreelaser 6000W laser cutting machine cuts 30mm carbon steel cutting, the sub-material is completely separated from the parent-material and the surface section is clean and tidy, the bottom is smooth and there is no dross.

What does high cutting quality bring?

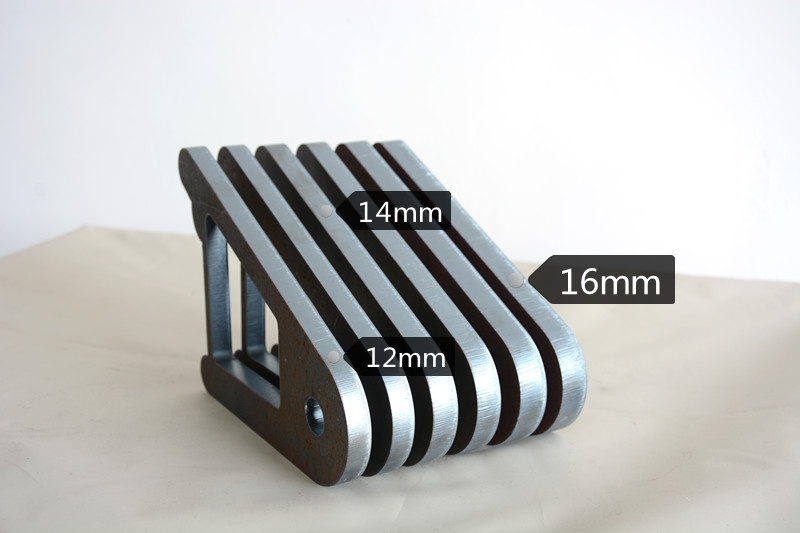

Oreelaser OR-P series full-enclosed laser cutting machine high-quality cutting eliminates the need for grinding and other steps in the subsequent welding process, saving secondary grinding costs, reducing environmental dust pollution and achieving green processing.

Application field

With the diversification of demand in the metal processing industry, the expansion of construction machinery, shipbuilding industry and other applications, the thickness of cutting low carbon steel have exceeded 30mm. To maintain a good welding effect, many technicians pay special attention to the process technology of cutting low carbon steel to improving the cutting quality of the cutting thick plate.

Professional Laser Cutting Machine Manufacturer - OreeLaser